There’s a new inflation warning for consumers coming from the supply chain

An Optoro warehouse in Tennessee that handles returns for retailers.

Source: Matt Adams | Optoro

As the markets prepare for the latest consumer price index data to be released on Tuesday, logistics managers are warning of a persistent source of inflation in the supply chain and saying consumers should be ready for the effect it will have on their wallets.

While many sources of supply chain inflation that stoked higher goods prices have come down sharply — including ocean freight rates and transportation fuels — bloated inventories due to a lack of consumer demand are sustaining upward pressure on warehouse rates.

“In 2022, we saw rate levels for international air and ocean and domestic trucking fall back down to earth,” said Brian Bourke, global chief commercial officer at SEKO Logistics. “But inflationary pressures remain where demand outpaces supply in 2023, including in warehousing through most of the United States, domestic parcel and labor.”

One reason for the imbalance between warehouse supply and demand is the lack of new facilities coming into the market.

“National warehousing capacity remains low and will remain tight for the foreseeable future as U.S. industrial construction starts have fallen considerably year-over-year due to rising interest rates,” said Chris Huwaldt, vice president of solutions at WarehouseQuote.

Consumer prices have come down sharply as goods inflation that surged during the pandemic has cooled. And Federal Reserve Chairman Jerome Powell expressed confidence after the most recent Fed meeting that disinflation “has begun.” December’s CPI was the smallest year-over-year increase since October 2021, at 6.5% on an annual basis, down from a 9.1% peak in June 2022.

The Fed is now more focused on services inflation, in particular labor prices, as it expects the pressure in goods inflation to continue a downward trend. But the logistics issues suggest there will be some elements of sticky inflation on the goods side of the equation.

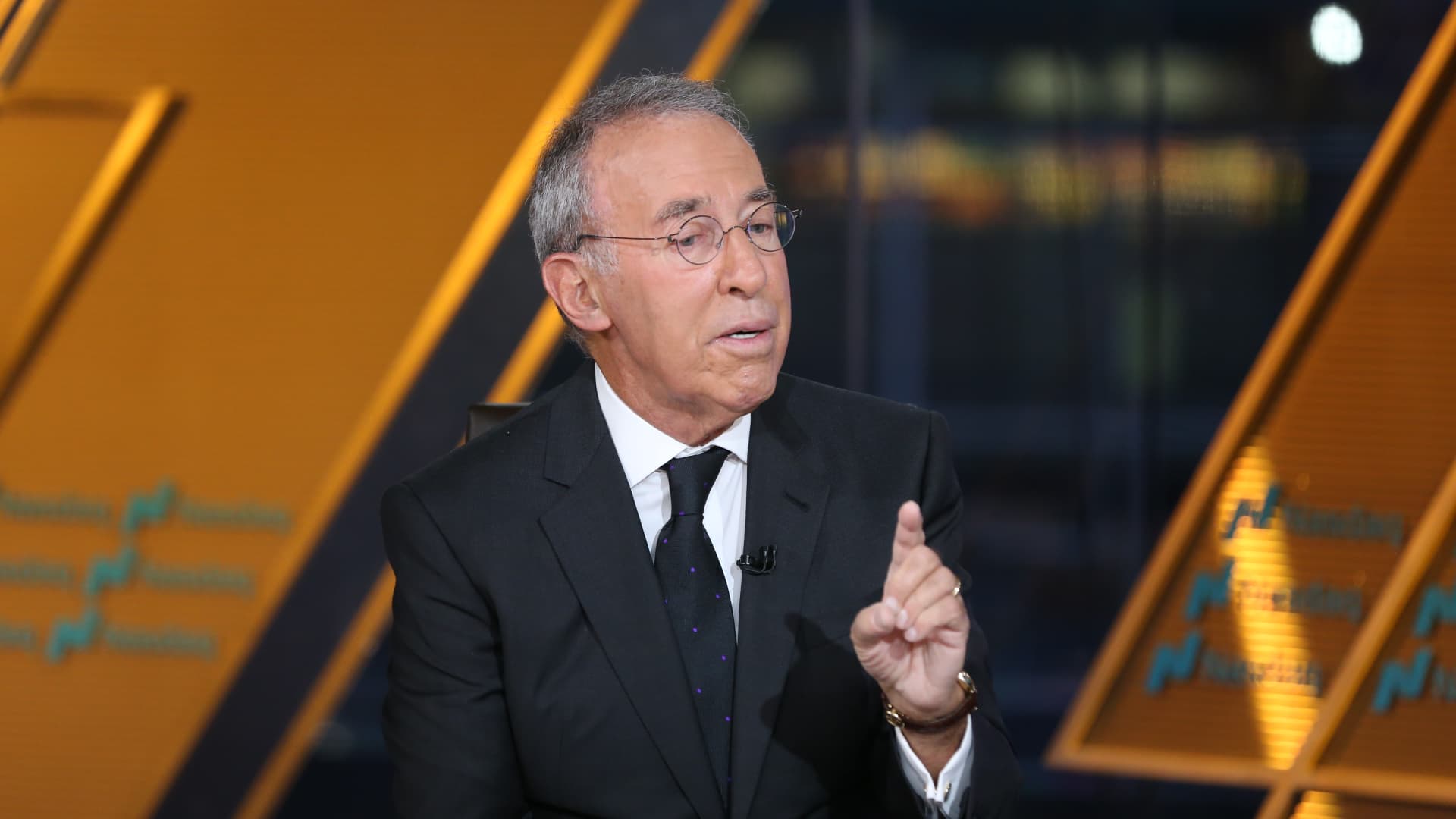

“The market is starting to sense that the very comforting disinflation story is more complex than we would like it to be,” Mohamed El-Erian, Allianz chief economic advisor, told CNBC’s “Squawk Box” on Monday morning. “The comforting story was simple: Goods disinflation continues and service inflation comes down, that wonderful concept that Chair Powell calls core services, ex-housing, comes down and, lo and behold, we don’t have an inflation problem. Now we’re starting to see certain goods reverse this inflationary process so there’s more uncertainty about inflation.”

Some shippers are holding their products in containers on chassis because of full warehouses and distribution centers, but this means they’re incurring charges which are passed on to the consumer. Shippers are given an allotted amount of free time during which they are not charged for holding a container, but once those days expire, they start to be charged per diem charges (i.e., late container charges that are charged for containers out of port).

Containers left on chassis create two costly problems, said Paul Brashier, vice president of drayage and intermodal for ITS Logistics. It prevents those chassis from being used to move newly arriving containers, putting additional stress on chassis pools throughout the U.S., especially inland rail ramp pools. Shippers will also be charged fees for the dwelling chassis — separate from the per diem charge shippers pay per day once the container is out of use beyond its free time. “This can lead to tens of millions of dollars in penalties,” Brashier said.

He predicts that per diem charges are going to surge in the second and third quarters of this year.

“These are on top of charges for warehousing, which are still at historic highs,” Brashier said. “Late fees and warehouse fees are passed onto the consumer, which is why we are not seeing products fall as much as they should.”

Shipping containers at a container terminal at the Port of Long Beach-Port of Los Angeles complex, in Los Angeles, California, April 7, 2021.

Lucy Nicholson | Reuters

National storage pricing is up 1.4% month-over-month and 10.6% year-over-year, according to WarehouseQuote.

Many small businesses, which represent the largest share of the U.S. economy in number but are often the last to benefit from a decline in supply chain pricing, tell CNBC they do not believe inflation has peaked.

For shippers with inventory imbalances, Brashier says these charges could cost tens of millions of dollars per quarter. Brashier warns these charges, on top of weaker consumer demand, will ripple through earnings.

ITS Logistics is advising clients to avoid a hit to their bottom line by considering short-term, pop-up storage offered by third-party logistics providers, or 3PL, and grounding operations. “This will reduce reliance on storing freight in ocean containers,” Brashier said.

3PL providers include C.H. Robinson, Expeditors, UPS Supply Chain Solutions, Kuehne + Nagel (Americas), J.B. Hunt, XPO Logistics, GXO Logistics, Uber Freight, and DHL Supply Chain (North America).

Mark Baxa, president and CEO of the Council of Supply Chain Management Professionals, tells CNBC that inflation and higher interest rates are driving supply chain leaders to critically examine working capital investments in inventory and operations in relation to consumer demand forecasts.

“In the short run, supply chains have moved closer to finance teams to manage cash flow, coupled with greater efforts to manage costs across operations. Considerations have moved to close-in review and total cost management across the business, including people, technology, warehousing and transportation investments,” Baxa said.

One industry facing supply chain inflationary headwinds is construction.

Phillip Ross, accounting and audit practice leader of Anchin’s architecture and engineering group, said supply chain inflation has made it more difficult for companies to manage completion times for projects.

“In some cases, we are looking at six to eight months before materials will be available,” Ross said. “Construction, as one of the largest industries in the U.S., is uniquely impacted by the supply chain, which led to construction companies experiencing not only delays in their work but also increased prices for materials.”

Some inflationary elements stemming from Covid-related supply chain disruptions remain, according to Jim Monkmeyer, president of transportation at DHL Supply Chain. These include higher costs related to diversion of containers to East Coast ports, production disruptions and shortages in China and elsewhere, and intermodal constraints forcing higher cost alternatives, such as air freight and expedited truck.

Even with the rate of inflation slowing, higher consumer prices are expected to remain for a variety of other reasons, from contract terms set with suppliers before recent disinflation and company desire to maintain profit margins.

Steve Lamar, CEO of the American Apparel and Footwear Association, tells CNBC that shippers are also finding it harder to absorb extra costs as a result of the Trump-Biden tariffs on China. “These tariffs are now hitting $170 billion and are baked into the cost of goods and, hence, higher prices at the register,” Lamar said. “The tariffs make it harder for companies to absorb other inflationary costs.”